Table of content:

The Role of Tungsten Carbide Composite Rod in Modern Manufacturing

Expert Insights: Selecting the Best Tungsten Carbide Rods Suppliers

How Leading Manufacturers Use Tungsten Carbide Rods to Enhance Durability

Cost-Effective Solutions with Tungsten Carbide Rods

The Role of Tungsten Carbide Composite Rod in Modern Manufacturing

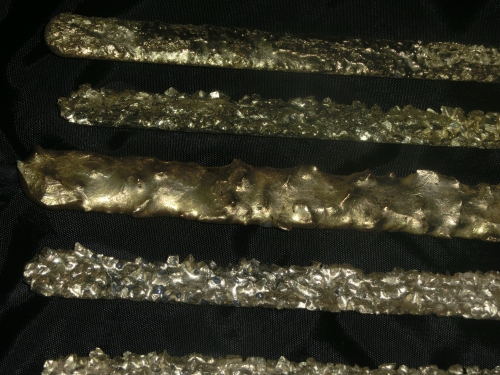

Tungsten carbide composite rods play a crucial role in modern manufacturing due to their unparalleled strength and wear resistance. These rods are composed of tungsten carbide particles bonded together, which results in a material that can withstand extreme conditions. Industries such as aerospace, automotive, and mining heavily rely on tungsten carbide rods for their applications. The ability of these rods to maintain their integrity under high pressure and temperature makes them ideal for cutting and drilling tools. Moreover, the use of tungsten carbide composite rods significantly reduces downtime and maintenance costs, contributing to overall operational efficiency. As manufacturers strive to meet the demands of a competitive market, the adoption of tungsten carbide composite rods is a strategic move that promises enhanced performance and longevity.

Expert Insights: Selecting the Best Tungsten Carbide Rods Suppliers

Choosing the right tungsten carbide rods suppliers is a critical decision that can impact the quality and performance of the final product. When selecting suppliers, manufacturers must consider factors such as the supplier's reputation, quality assurance processes, and delivery capabilities. A reliable supplier will offer consistent quality and adhere to industry standards, ensuring that the tungsten carbide rods meet the specific requirements of the application. Additionally, manufacturers should look for suppliers who provide technical support and have a comprehensive understanding of the material's properties. This partnership can lead to innovative solutions and improved product performance. By collaborating with reputable suppliers, manufacturers can secure a steady supply of high-quality tungsten carbide rods, which in turn enhances their production capabilities and market competitiveness.

How Leading Manufacturers Use Tungsten Carbide Rods to Enhance Durability

Leading manufacturers have long recognized the benefits of using tungsten carbide rods to enhance the durability of their products. These rods are integral in the production of cutting tools, where precision and longevity are paramount. The hardness of tungsten carbide allows tools to maintain sharp edges for longer periods, reducing the need for frequent replacements. Moreover, the wear resistance of these rods ensures that equipment operates efficiently even under the most demanding conditions. By incorporating tungsten carbide rods into their manufacturing processes, companies can produce components that offer superior performance and reliability. This not only extends the lifespan of the products but also contributes to customer satisfaction and brand loyalty. As technology advances, the role of tungsten carbide rods in achieving durable and high-performing products will continue to grow.

Cost-Effective Solutions with Tungsten Carbide Rods

In today's competitive market, manufacturers are constantly seeking cost-effective solutions that do not compromise on quality. Tungsten carbide rods offer an ideal solution, providing exceptional value for money. The initial investment in tungsten carbide may be higher compared to other materials, but the long-term benefits far outweigh the costs. The durability and wear resistance of tungsten carbide rods result in fewer replacements and lower maintenance expenses. Additionally, the efficiency gained from using these rods can lead to increased production output and reduced downtime. Manufacturers who adopt tungsten carbide rods can achieve significant cost savings while maintaining high standards of quality and performance. As the industry continues to evolve, the strategic use of tungsten carbide rods will remain a key factor in achieving cost-effective manufacturing solutions.

In conclusion, tungsten carbide rods have become an indispensable component in modern manufacturing, offering unmatched durability and efficiency. From the selection of reliable suppliers to the strategic application in production processes, the use of tungsten carbide rods provides a competitive edge to manufacturers. By embracing this advanced material, companies can enhance product performance, reduce costs, and ultimately achieve greater success in the marketplace. As the demand for high-quality and cost-effective solutions grows, the role of tungsten carbide rods in shaping the future of manufacturing is undeniable.

Comments

Post a Comment