Table of contents:

Key Features of Modern Shaker Screens and Their Impact

Replacement Shaker Screens: Reducing Waste and Costs

How Shaker Screens Manufacturers are Meeting Industry Demands

The Growing Demand for Wholesale Shaker Screens in 2025

Key Features of Modern Shaker Screens and Their Impact

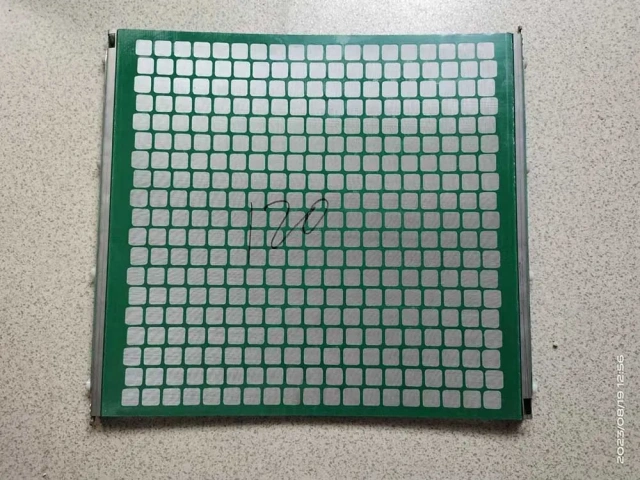

Modern shaker screens, like the Axion-1, are pivotal in advancing drilling technology. Their design focuses on high-performance solids control and durability, ensuring optimal operation with shale shakers equipped with dual 5 kW VFD motors. Operating at frequencies of 50-67 Hz and delivering 5-7 G force, these screens are engineered to meet demanding industry standards. The importance of such features cannot be overstated, as they directly impact the efficiency and cost-effectiveness of drilling operations. Shaker Screens manufacturers are continually innovating to improve these features, ensuring that the screens are not only robust but also adaptable to various drilling conditions. As the industry evolves, the focus on enhancing screen performance remains a priority to support the growing demands of global drilling projects.

Replacement Shaker Screens: Reducing Waste and Costs

The introduction of replacement shaker screen supply has revolutionized the approach to drilling equipment maintenance. By focusing on the replacement of only the mesh, rather than the entire screen, significant reductions in waste and costs are achieved. This approach is particularly beneficial in terms of environmental sustainability, as it minimizes the disposal of non-degradable materials. Shaker Screens manufacturers are at the forefront of this movement, providing solutions that align with both economic and ecological objectives. The Axion-1 screen, with its innovative design, exemplifies this trend, offering a practical solution to the challenges of waste management in the drilling industry. By reducing consumable waste, companies can allocate resources more efficiently, ultimately enhancing their bottom line.

How Shaker Screens Manufacturers are Meeting Industry Demands

The drilling industry is characterized by its dynamic and demanding nature, requiring Shaker Screens manufacturers to be agile and responsive. Manufacturers like PRM Drilling have risen to the challenge, offering high-quality drilling equipment and services that emphasize experience, quality assurance, and innovative solutions. Their customer-centric approach ensures that they not only meet but exceed industry demands. With a global network for timely support, they provide a comprehensive range of products, including rotary drilling rigs and customized solutions. Their services extend beyond equipment sales to include rentals, maintenance, repair, and consulting, ensuring efficient drilling operations. The commitment to innovation and customer satisfaction is evident in their ability to adapt to the changing needs of the industry, reinforcing their position as leaders in the field.

The Growing Demand for Wholesale Shaker Screens in 2025

As the drilling industry continues to expand, the demand for wholesale Shaker Screens is projected to grow significantly by 2025. This increase is driven by the need for cost-effective solutions that can be deployed quickly and efficiently across various drilling sites worldwide. Wholesale Shaker Screens offer an economical advantage, allowing companies to purchase in bulk and reduce overall procurement costs. Shaker Screens manufacturers are poised to meet this demand, leveraging their expertise and production capabilities to supply high-quality screens at competitive prices. The Axion-1 Replacement Shaker Screen is a prime example of a product that meets these criteria, providing exceptional performance and reliability. As companies seek to optimize their operations, the role of wholesale shaker screens will become increasingly critical in ensuring the success of drilling projects.

In summary, the Axion-1 Replacement Shaker Screen represents a significant advancement in drilling technology, offering innovative solutions to enhance operational efficiency and reduce costs. With features designed to meet the rigorous demands of the industry, it exemplifies the commitment of Shaker Screens manufacturers to provide high-quality, sustainable products. As the demand for wholesale shaker screens continues to rise, companies like PRM Drilling are well-positioned to lead the charge, ensuring that they remain at the forefront of industry innovation and customer satisfaction.

Comments

Post a Comment